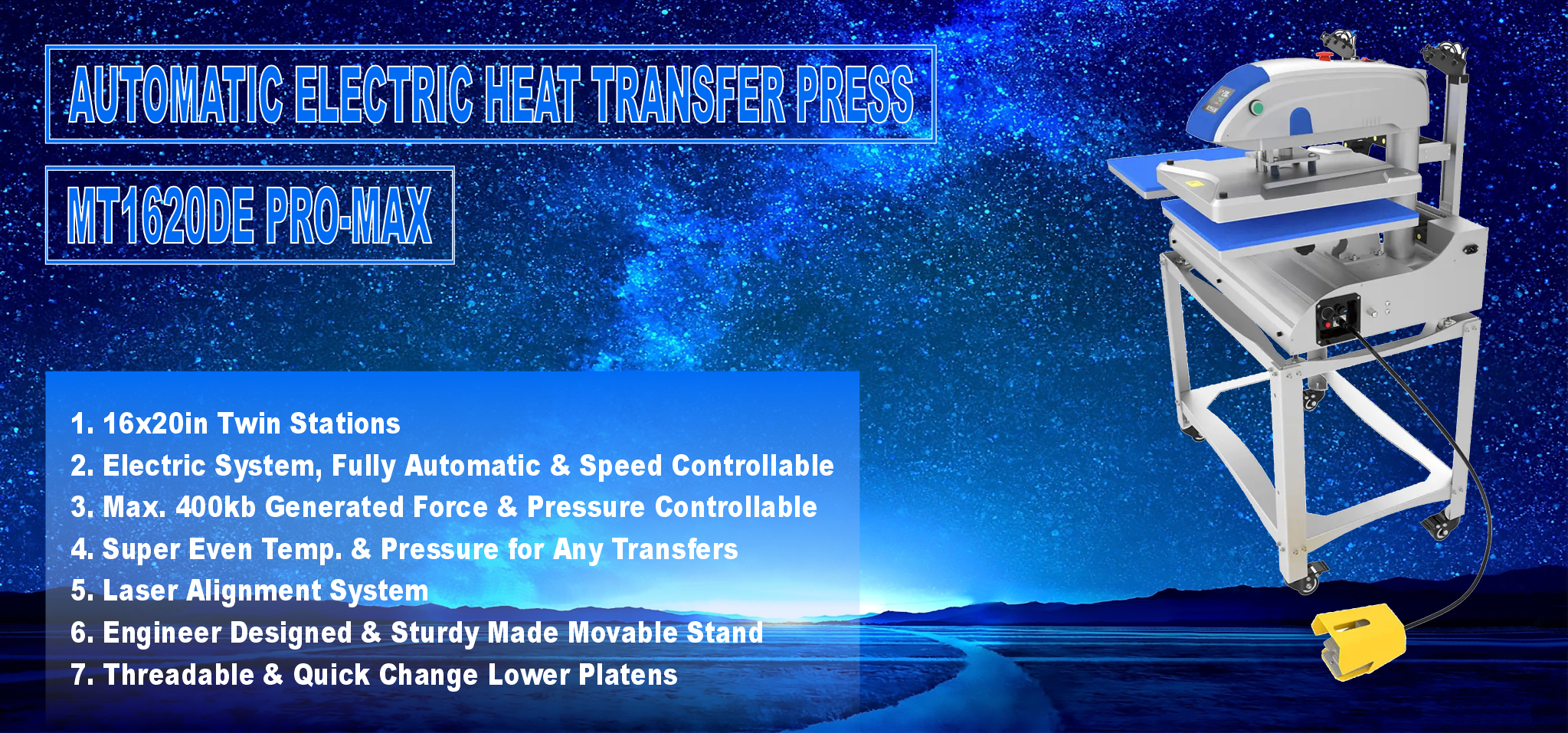

Model No:MT1620DE-ProMax

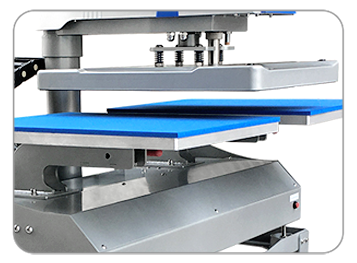

This electronic dual platen heat press is our top-of-the-line machine when it comes to mass production at high quality levels. Powered by electric gear technology with Max. 400kg heat pressing for heavy pressure application, this unit can handle anything – large or small garments, multiple ceramic tiles, and many other substrates. It does not require compressed air, which makes it more convenient. It features high efficiency & excellent pressure, can operate in full-auto, or semi-auto modes.

Style: Dual Platen Electric Heat Press

Features: Twin Platen, Electric, Shuttle, Interchangeable, Threadable

Platen Size: 40 x 50cm

Dimension: 94.7x82x71.7cm

Certificate: CE (EMC, LVD, RoHS)

Warranty: 1 Year

$3,659.00

2 in stock

Features:

This upgraded version with a moveable heat table and laser locator, is our top of the line fully electronic heat press. It offers highly efficient mass production at high quality levels. This unit can handle anything – large or small garments, multiple ceramic tiles, and many other substrates. It does not require compressed air, which makes it more convenient. It features high efficiency & excellent pressure and can operate in full-auto, or semi-auto modes. Its speed moving from left to right is adjustable. Full-range repeatable pressure adjustments for items up to 4.5cm thick, LCD screen controller, and live digital time, accurate temperature read-out and Max. 120min set automatic stand-by.

Two thermal protection decices connect separately with live wire and Neutral Wire, the third protection is heating plate with temperature protector which prevents abnormal temperature rise.

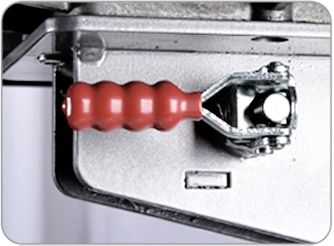

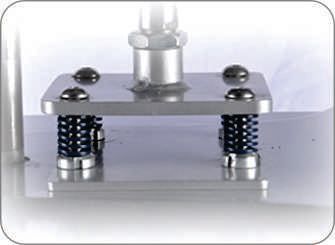

This MoreTranz Heat Press is installed with a featured base: 1. Quick changeable system enables you to change the different accessory platen in few seconds. 2. The thread-able base enables you to load or rotate the garment over the lower platen.

This heat press is also equipped with advanced LCD controller AT700 series, super precise in Temp control and read-out. User could set the applying pressure by controller setting (P-4 mode). The controller is also featured with Max. 120mins stand-by function (P-5 mode) make it energy saving and safety.

The electric dual station heat press transitions from platen to platen, allowing you to thread and remove garments quickly and easily.

A pop-up controller makes instrument replacement easier.

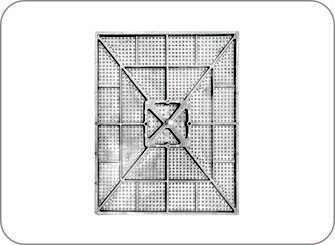

There is enough size to print all kinds of products.

Protective Cap is safer and anti-scalding.

Ensure balanced pressure distribution.

Ensures Sufficient thickness for major substrates.

Specifications:

Heat Press Style: Electric

Motion Available: Swing-away/ Auto-Open

Heat Platen Size: 40x50cm

Voltage: 110V or 220V

Power: 1800-2200W

Controller: Screen-touch LCD Panel

Max. Temperature: 450°F/232°C

Timer Range: 999 Sec.

Machine Dimensions: 94.7 x 82 x 72cm

Machine Weight: 125kg

Shipping Dimensions: 110 x 83 x 87cm

Shipping Weight: 140kg

CE/RoHS compliant

1 Year entire warranty

Lifetime technical support

| Weight | 310 lbs |

|---|---|

| Dimensions | 44 × 34 × 36 in |

Reviews

There are no reviews yet.